Saturday, May 31, 2014

Friday, May 30, 2014

Final Arduino Code

I finally got the code to work and do everything I want (mostly)...

// Perpetual Windmill USB Charger for Arduino

// Kyle Thatcher

// Last Modified -- May 30, 2014

////////////////////////////////////////////

////////////////////////////////////////////

#include <Servo.h>

int pinMill = A0; // input pin for the brushless motor phase sensor

int sensor[] = {0,0}; // stores the current sensor reading [0] and the previous sensor reading [1]

long i = 0; // keeps count of revolutions of mill motor

long millRPM = 0; // stores the RPM calculated from the mill motor's phase sensor

unsigned long t[] = {0,0}; // the elapsed time [0] and previous time at elapse [1]

Servo fan; // creates a servo object

int pinFan = 9; // output pin for PPM (servo) fan motor ESC

float battVolts = 7.4; // the nominal voltage of the battery in use (7.4 or 11.1)

int kV = 1000; // the kV value (RPM/Volt) of fan motor

int fanRPM = 0; // stores the fans intended RPM

int maxFanRPM = 1000; // the maximum fan RPM desired

int initVal = 18; // the minimum value that the ESC will use

int val; // the PPM value (18-179) to output to the ESC

int pinUSB = 4; // the output pin for controlling USB charging port

////////////////////////////////////////////

void setup()

{

pinMode(pinMill, INPUT);

fan.attach(pinFan);

pinMode(pinUSB, OUTPUT);

fan.write(initVal);

digitalWrite(pinUSB, LOW);

Serial.begin(9600);

Serial.println("Initializing");

}

////////////////////////////////////////////

void loop()

{

// What is the mill's RPM //

sensor[0] = digitalRead(pinMill);

if ( sensor[0] == 1 && sensor[1] == 0) ++i;

sensor[1] = sensor[0];

t[0] = millis() - t[1];

if ( t[0] >= 200 )

{

millRPM = 1000 * i / t[0];

i = 0;

t[1] = millis();

}

// Control ESC (fan speed) values from 18-179 //

if ( millRPM >= 15 )

{

//fanRPM = 2 * millRPM;

//if ( fanRPM > 100 ) fanRPM = 100;

//val = ( fanRPM * 255 ) / ( kV * battVolts );

val = 75;

}

else

{

val = initVal;

}

fan.write(val);

// Control USB Charging Port //

if ( millRPM >= 20 ) digitalWrite(pinUSB, 1);

else digitalWrite(pinUSB, 0);

//digitalWrite(pinUSB, 1);

// Print Debug Values //

//Serial.println(millRPM);

delay(1);

}

////////////////////////////////////////////

////////////////////////////////////////////

// Perpetual Windmill USB Charger for Arduino

// Kyle Thatcher

// Last Modified -- May 30, 2014

////////////////////////////////////////////

////////////////////////////////////////////

#include <Servo.h>

int pinMill = A0; // input pin for the brushless motor phase sensor

int sensor[] = {0,0}; // stores the current sensor reading [0] and the previous sensor reading [1]

long i = 0; // keeps count of revolutions of mill motor

long millRPM = 0; // stores the RPM calculated from the mill motor's phase sensor

unsigned long t[] = {0,0}; // the elapsed time [0] and previous time at elapse [1]

Servo fan; // creates a servo object

int pinFan = 9; // output pin for PPM (servo) fan motor ESC

float battVolts = 7.4; // the nominal voltage of the battery in use (7.4 or 11.1)

int kV = 1000; // the kV value (RPM/Volt) of fan motor

int fanRPM = 0; // stores the fans intended RPM

int maxFanRPM = 1000; // the maximum fan RPM desired

int initVal = 18; // the minimum value that the ESC will use

int val; // the PPM value (18-179) to output to the ESC

int pinUSB = 4; // the output pin for controlling USB charging port

////////////////////////////////////////////

void setup()

{

pinMode(pinMill, INPUT);

fan.attach(pinFan);

pinMode(pinUSB, OUTPUT);

fan.write(initVal);

digitalWrite(pinUSB, LOW);

Serial.begin(9600);

Serial.println("Initializing");

}

////////////////////////////////////////////

void loop()

{

// What is the mill's RPM //

sensor[0] = digitalRead(pinMill);

if ( sensor[0] == 1 && sensor[1] == 0) ++i;

sensor[1] = sensor[0];

t[0] = millis() - t[1];

if ( t[0] >= 200 )

{

millRPM = 1000 * i / t[0];

i = 0;

t[1] = millis();

}

// Control ESC (fan speed) values from 18-179 //

if ( millRPM >= 15 )

{

//fanRPM = 2 * millRPM;

//if ( fanRPM > 100 ) fanRPM = 100;

//val = ( fanRPM * 255 ) / ( kV * battVolts );

val = 75;

}

else

{

val = initVal;

}

fan.write(val);

// Control USB Charging Port //

if ( millRPM >= 20 ) digitalWrite(pinUSB, 1);

else digitalWrite(pinUSB, 0);

//digitalWrite(pinUSB, 1);

// Print Debug Values //

//Serial.println(millRPM);

delay(1);

}

////////////////////////////////////////////

////////////////////////////////////////////

Thursday, May 29, 2014

inConstruction

I finally got all my parts laser cut from the Acrylic. Yesterday I solvent glued together the base. Now on to the fun part.

Here I am set up at home with all the circuitry components laid out and ready to solder together.

Wednesday, May 28, 2014

Initial Arduino Code

The process of developing the Arduino code has also a great way for me to organize my ideas. It forces me to write down there verminous aspects of the project in a symbolic, systematic and sequenced structure. My initial

// Perpetual Windmill USB Charger for Arduino

// thatchek

// Last Modified -- May 28, 2014

////////////////////////////////////////////

////////////////////////////////////////////

int pinRPM = 7; // input pin for the brushless motor phase sensor

int sensor[] = {0,0}; // stores the current sensor reading [0] and the previous sensor reading [1]

long i = 0; // keeps count of revolutions of mill motor

long millRPM = 0; // stores the RPM calculated from the mill motor's phase sensor

unsigned long t[] = {0,0}; // the elapsed time [0] and previous time at elapse [1]

int pinMotor = 9; // output pin for PWM fan motor ESC

float battVolts = 7.4; // the nominal voltage of the battery in use

int kV = 1000; // the kV value (RPM/Volt) of fan motor

int fanRPM = 0; // stores the fans intended RPM

int maxFanRPM = 1000; // the maximum fan RPM desired

float fanVal = 0; // the PWM value (0-255) to output to the ESC

int pinUSB = 4; // the output pin for controlling USB charging port

////////////////////////////////////////////

void setup()

{

pinMode(pinRPM, INPUT);

pinMode(pinMotor, OUTPUT);

pinMode(pinUSB, OUTPUT);

digitalWrite(pinUSB, LOW);

Serial.begin(9600);

Serial.println("Initializing");

}

////////////////////////////////////////////

void loop()

{

// What is the mill's RPM //

sensor[0] = digitalRead(pinRPM);

if ( sensor[0] == 1 && sensor[1] == 0) ++i;

sensor[1] = sensor[0];

t[0] = millis() - t[1];

if ( t[0] >= 200 )

{

millRPM = 1000 * i / t[0];

i = 0;

t[1] = millis();

}

// Control ESC (fan speed) values from 0 to 255 //

if ( millRPM >= 10 )

{

fanRPM = 2 * millRPM;

if ( fanRPM > 500 ) fanRPM = 500;

fanVal = ( fanRPM * 255 ) / ( kV * battVolts );

}

else

{

fanVal = 0;

}

analogWrite(pinMotor, fanVal);

// Control USB Charging Port //

if ( millRPM >= 50 ) digitalWrite(pinUSB, HIGH);

else digitalWrite(pinUSB, LOW);

// Print Debug Values //

// Serial.println();

delay(10);

}

////////////////////////////////////////////

////////////////////////////////////////////

// Perpetual Windmill USB Charger for Arduino

// thatchek

// Last Modified -- May 28, 2014

////////////////////////////////////////////

////////////////////////////////////////////

int pinRPM = 7; // input pin for the brushless motor phase sensor

int sensor[] = {0,0}; // stores the current sensor reading [0] and the previous sensor reading [1]

long i = 0; // keeps count of revolutions of mill motor

long millRPM = 0; // stores the RPM calculated from the mill motor's phase sensor

unsigned long t[] = {0,0}; // the elapsed time [0] and previous time at elapse [1]

int pinMotor = 9; // output pin for PWM fan motor ESC

float battVolts = 7.4; // the nominal voltage of the battery in use

int kV = 1000; // the kV value (RPM/Volt) of fan motor

int fanRPM = 0; // stores the fans intended RPM

int maxFanRPM = 1000; // the maximum fan RPM desired

float fanVal = 0; // the PWM value (0-255) to output to the ESC

int pinUSB = 4; // the output pin for controlling USB charging port

////////////////////////////////////////////

void setup()

{

pinMode(pinRPM, INPUT);

pinMode(pinMotor, OUTPUT);

pinMode(pinUSB, OUTPUT);

digitalWrite(pinUSB, LOW);

Serial.begin(9600);

Serial.println("Initializing");

}

////////////////////////////////////////////

void loop()

{

// What is the mill's RPM //

sensor[0] = digitalRead(pinRPM);

if ( sensor[0] == 1 && sensor[1] == 0) ++i;

sensor[1] = sensor[0];

t[0] = millis() - t[1];

if ( t[0] >= 200 )

{

millRPM = 1000 * i / t[0];

i = 0;

t[1] = millis();

}

// Control ESC (fan speed) values from 0 to 255 //

if ( millRPM >= 10 )

{

fanRPM = 2 * millRPM;

if ( fanRPM > 500 ) fanRPM = 500;

fanVal = ( fanRPM * 255 ) / ( kV * battVolts );

}

else

{

fanVal = 0;

}

analogWrite(pinMotor, fanVal);

// Control USB Charging Port //

if ( millRPM >= 50 ) digitalWrite(pinUSB, HIGH);

else digitalWrite(pinUSB, LOW);

// Print Debug Values //

// Serial.println();

delay(10);

}

////////////////////////////////////////////

////////////////////////////////////////////

Learning?

Reflecting on my design process thus far, I find myself rather disappointed... and I am realizing that this tends to be the norm for me. I am disappointed that I seem to always start a project with a ambitious goals. I incorporate a certain robust elegance into my designs. However, as it always happens, time and money decidedly ruin the day. I must learn to better optimize my design path in order to incorporate a cost effectiveness into my process. I think if I can manage to start with this as a design criteria, it may influence my creative drive to strive for economy.

Never the less, I am interested in witnessing the reactions to my Perpetual Windmill. I have never used my engineering background to produce a product solely for artistic value. This have been a challenging yet very rewarding experience for my educational development.

Never the less, I am interested in witnessing the reactions to my Perpetual Windmill. I have never used my engineering background to produce a product solely for artistic value. This have been a challenging yet very rewarding experience for my educational development.

Solid Modeling

I personally like to use 3-D modeling in my design process. It allows me the opportunity to sketch in three dimensions and better visualize the idea that is in my head. I really like the ability to see the way certain curves in my design react visually to other curves... something that I have a hard time doing in just my imagination.

Initial SolidWorks rendering:

This is my idea of the base of my sculpture. It is made from laser cut 0.22 inch clear acrylic sheeting that is then solvent glued together to form a three dimensional shape.

Initial SolidWorks rendering:

This is my idea of the base of my sculpture. It is made from laser cut 0.22 inch clear acrylic sheeting that is then solvent glued together to form a three dimensional shape.

Hierarchy of Needs

Creativity

Interesting and ironic statement of energy efficiency

Proficiency

Nothing to learn... just start the windmill turning

Usability

So easy a child can do it... just might not understand

Reliability

Once the windmill is turning, it needs to keep turning

Functionality

Windmill must be turned by fan

Friday, May 23, 2014

AC Motor Specs

Neewer A2212/13 KV1000

- No load Current: 10 V : 0.5 A.

- Maximum current: 12A/60s.

- Apply to the ESC: 30A.

- Apply to the Lipo: 2 - 3S.

- Apply to the NiCD / NiMH: 6 - 9S.

- Apply to the Propeller: 8x4.5" 9x4.5" 10x4.5" 10x4.7".

- Apply to the three Propeller: 7x4.5" 8x4.5" 9x4.5".

- Shaft diameter: 3.175mm.

- Weight: 2.20oz

the SHIFT design

I finally received a lecture specifically on design aesthetics. This lecture was wonderful and very inspirational for my conditioned engineering brain. My focus previously on this project was on the mechanics of the design... "what is the result of this artifact?" Totally absorbed, as you are trained to be, in the numbers. How much wind is needed for which winding of generator to achieve the desired wattage output!?!? I was almost entirely neglecting the artistic side of design... what is my project saying and what does it mean to the user?

Thus, I am shifting my design to an ironic sculpture aesthetic. I am now going to build a "perpetual" fan powered wind generator. This is illustrated by some sketches below.

From this process of sketching critical design components of the project, I was able to more accurately decide on a design path for the project. My new design sketch is as follows.

Details:

- Laser cut acrylic base/stand

- Two 30A 1000Kv three phase motors... one powered via ESC and the other providing RPM sensor information

- Hidden 2200mAh Lipo, RPM switch, and USB charging port

- 8x4.5" carbon fiber propeller blade as "fan"

- Lawn art flower windmill as "windmill"

Team Interaction

This is where I tell you about how I work in teams. Not very well. I am the jerk that takes over everything. I always think I have a better way of doing thing. However, I am not a one to criticize without providing a solution.

For this project, I am working in a team a three. Each team member is responsible for their own work which actually suits my jerk mentality. I give as many suggestions as I can but in the end it is up to the individual to implement their unique idea.

For this project, I am working in a team a three. Each team member is responsible for their own work which actually suits my jerk mentality. I give as many suggestions as I can but in the end it is up to the individual to implement their unique idea.

Wednesday, May 21, 2014

Design Loop

The engineering design loop, is really more of a web. There is no one correct design process. My personal process thus far in this project has been:

Generate Concepts -> Define Problems -> Recognize Need -> Gatherer Info -> Generate Concepts

Critical Constraints

After reflection upon the task that lies ahead, a few critical constraints were identified.

- Time (this project needs to be completed by May 30, 2014)

- Monetary (it is very easy to go over budget with a project like this)

- Functionality (the project needs to actually do what is supposed to do)

- Quality (I am a bit of a perfectionist)

- Environmental (what good is an energy saving windmill if it is made from mercury and lead)

These constraints will shape the remainder of this project.

Tuesday, May 20, 2014

Electronics

Typical USB charging information:

- Voltage 5.00 +- 0.25 V

- Amperage 0.5 - 0.9 A (up to 5 A for some charging units)

- Wattage 5 V * 1 A ~ 5 W

Generator:

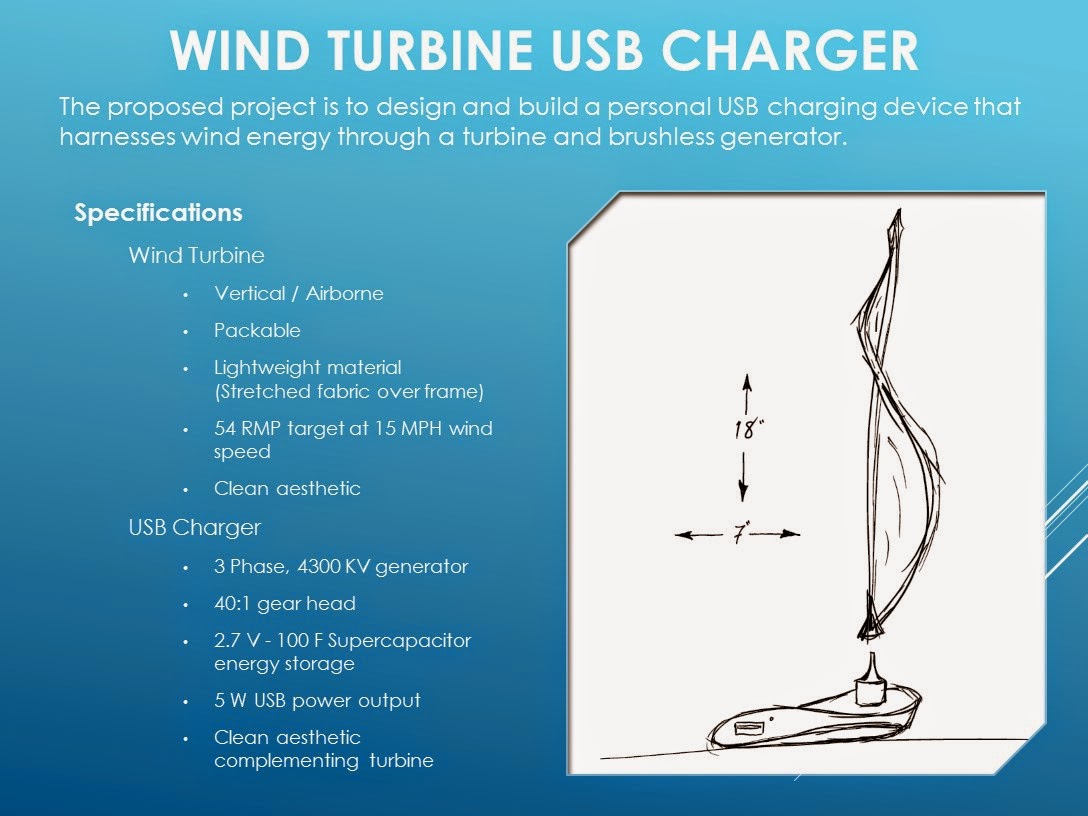

After doing some research, I found a three phase generator that matched the USB charging power requirements. The generator is actually a hobby motor used in small RC cars.

This generator is a 14 turn 4 pole and has a 4300 KV rating. This means that for every 4300 RPM the generator is spun, it outputs 1 volt. Expected RPM for a typical wind turbine with a 15 MPH wind is ~100-300. This means that in order to achieve a 1 V output from the generator, the turbine would need to have an ~40:1 gear reduction.

A hex-bridge rectifier will convert the 3-phase alternating current into a direct current. The DC output of the rectifier will then feed a DC-DC boost converter to regulate the voltage at 5 V which will power the USB port.

A hex-bridge rectifier will convert the 3-phase alternating current into a direct current. The DC output of the rectifier will then feed a DC-DC boost converter to regulate the voltage at 5 V which will power the USB port.

Friday, May 16, 2014

Preliminary Design Review

Next steps are to...

- Order components

- Finalize design based on component specifications

- Begin construction

Thursday, May 15, 2014

Leaning Into The Wind

After thinking about my three ideas over night, I am leaning towards a windmill of some kind. I think that a windmill has more potential for aesthetic freedom (sorta the point of all this) and if it works well it is something I could potentially actually use. The engine model, although one day I will make one, is to large of a scope for my three week time frame. The plasma speaker is very cool, however, I have already built one in the past, not a finished aesthetic design however, but it is still nothing really new to learn.

An interesting windmill, however, I would love to install on my porch if it ends up being a purely artistic expression and would be super cool if it ends up also being able to charge my phone in on a camping trip. Thus I have decided to peruse the windmill / wind charger project.

Some interesting examples of wind turbine designs I have found:

An interesting windmill, however, I would love to install on my porch if it ends up being a purely artistic expression and would be super cool if it ends up also being able to charge my phone in on a camping trip. Thus I have decided to peruse the windmill / wind charger project.

Some interesting examples of wind turbine designs I have found:

http://webecoist.momtastic.com/wp-content/uploads/2008/12/9-anthony-howe-rooster-rings-sculpture.jpg

There are many beautiful and artistic windmill designs out in the world. However, nothing will ever beat the great garden flower twirly thing!!

Wednesday, May 14, 2014

Initial Ideas

There are several ideas that I have been wanting to design/build for awhile now and this might finally give me the perfect excuse to spend the time/money to actually do one of them.

Each idea posses a very different kind of aesthetic to me... they are:

Each idea posses a very different kind of aesthetic to me... they are:

- Magnetic Stirling Engine (form from function)

Engines,

typically tucked away under mountains of utilitarian garbage or hideous

decorative plastic, it is very rare to find an engine that is intended to be

beautiful. Personally, my favorite aesthetic is when the form follows the

function, however, I think this can be in elegant and non-elegant ways. I

always remember a quote I heard from a car designer once that went something

like, "... I like to think of the engine like a sparkling diamond, and the

car is its box. When you open the hood of a car, it should feel as though you

are opening an engagement ring box, where the engine is presented to you,

taking your breath away, and everything else just fade into the

background." Although not in a car, I think Huib Visser's model Stirling

engines are a perfect example of the beauty an engine can aspire to.

- Plasma Speaker (show casing)

By: jmartis2 (Video)

The plasma speaker is an example of a massless speaker design that results in ultra-high fidelity sound reproduction. It uses an electric plasma arc, controlled lightning, to create the pressure waves, controlled thunder, which we hear as sound. The magic of this process is in the utilization of pulse width modulation (PWM). The arc's clock frequency is first tuned far above the range of human hearing, usually around 80-100 KHz, rendering it silent. Then this high clock frequency is tuned on and off at the specific frequency of the sound to be produced. The aesthetic challenge of the plasma speaker is how to showcase such a cool and unusual technology. What proportion of internals should be left visible, should the plasma be seen directly or should just a glow of light be shown, what materials should be used, etc.

- Wind Powered USB charger (product)

By: MiniKin

A USB

charger is a perfect example of simple consumer product where its design has

very little to do with its function… this is why they almost all look like your

typical AC converter brick. However, with the addition of something dynamic,

like a wind turbine, the aesthetic of the product becomes a larger proportion

of the overall design intent.

Any suggestions?

Mission

Welcome to ThinkSHIFTdesigN

My mission is to create and "artifact" during the next three weeks in the University of Colorado's ITL Laboratory with the purpose of documenting my personal design/build process for AeDes research. This blog is the means for documenting this process and rendering it public domain.

My mission is to create and "artifact" during the next three weeks in the University of Colorado's ITL Laboratory with the purpose of documenting my personal design/build process for AeDes research. This blog is the means for documenting this process and rendering it public domain.

Subscribe to:

Comments (Atom)